Ericsson and the Fraunhofer Institute for Production Technology have teamed up to explore and develop industrial applications of 5G.

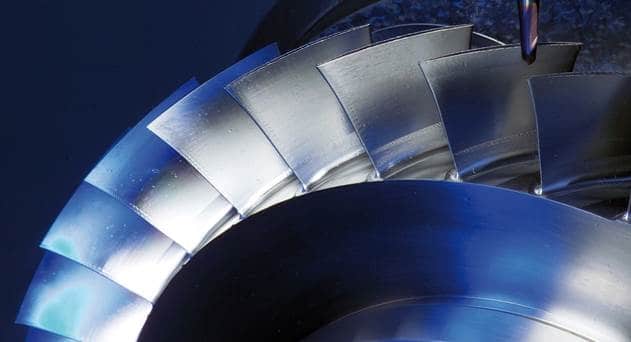

The first use case for production of jet engine components for MTU Aero Engines is currently being evaluated. The components concerned, so-called blade integrated disks (blisk), are high-tech components where the disk and blades are produced as a single piece and serve the purpose of compressing the air inside jet engines. They are milled out of solid pieces of metal and have extremely high requirements towards accuracy and surface integrity.

According to Ericsson, applying 5G in the manufacturing industry has many important benefits in terms of costs, quality, and flexibility. The ultra-low latency and very high bandwidth make it possible to control machines in real-time, reducing manufacturing costs and improving quality of products.

The 5G-enabled blisk case alone can save approximately EUR 27 million for one single factory, and up to EUR 360 million globally, according to the latest Ericsson Consumer and Industry Lab Business Value Report. From a sustainability perspective, CO2 emissions from both the production of blisk and their operation in jet engines can be reduced by some 16 million tons annually on a global basis.

Moreover, the fact that 5G is a wireless technology also means machines can be equipped with sensors where fixed connections cannot be installed, and production lines can easily be adapted to new requirements – in a fraction of a second, said Ericsson.

The Blisk pilot shows the technical capabilities of 5G such as ultra-low latency of close to 1 millisecond, which is vital for in-process, time-critical applications. Ericsson’s 5G trial system operating on 3.5 GHz is connected to an acceleration sensor mounted directly on the blisk in the production machinery. The vibration spectrum is transmitted in real time via 5G to the evaluation system. The very low latency helps correlate the vibration to the tool’s position and enable prompt adjustment of the production process.

The Blisk 5G use case is Ericsson's first published tangible case study where the company takes a closer look at the business value of 5G-enabled production.

Thomas Dauti, Director of Manufacturing Technology, MTU Aero Engines

A blade-integrated disk is a high-value component. The milling process takes 15-20 hours and the total lead time is around 3-4 months, including coating processes and quality checks. The new 5G-based production technology will help make our operations more efficient.

Arun Bansal, SVP and Head of Market Area Europe and Latin America, Ericsson

We are running 5G industry programs in Europe, North America and Asia. There is a strong demand from industries for 5G technology and together we can boost productivity and create new business opportunities.